What’s in Stock?

- Get real-time access to your stock status anytime.

- Every transaction in POS will update the stock levels as soon as they are transacted.

- Manage stocks from multiple warehouses and make them visible to all branches for better coordination.

Reduce Inventory Cost

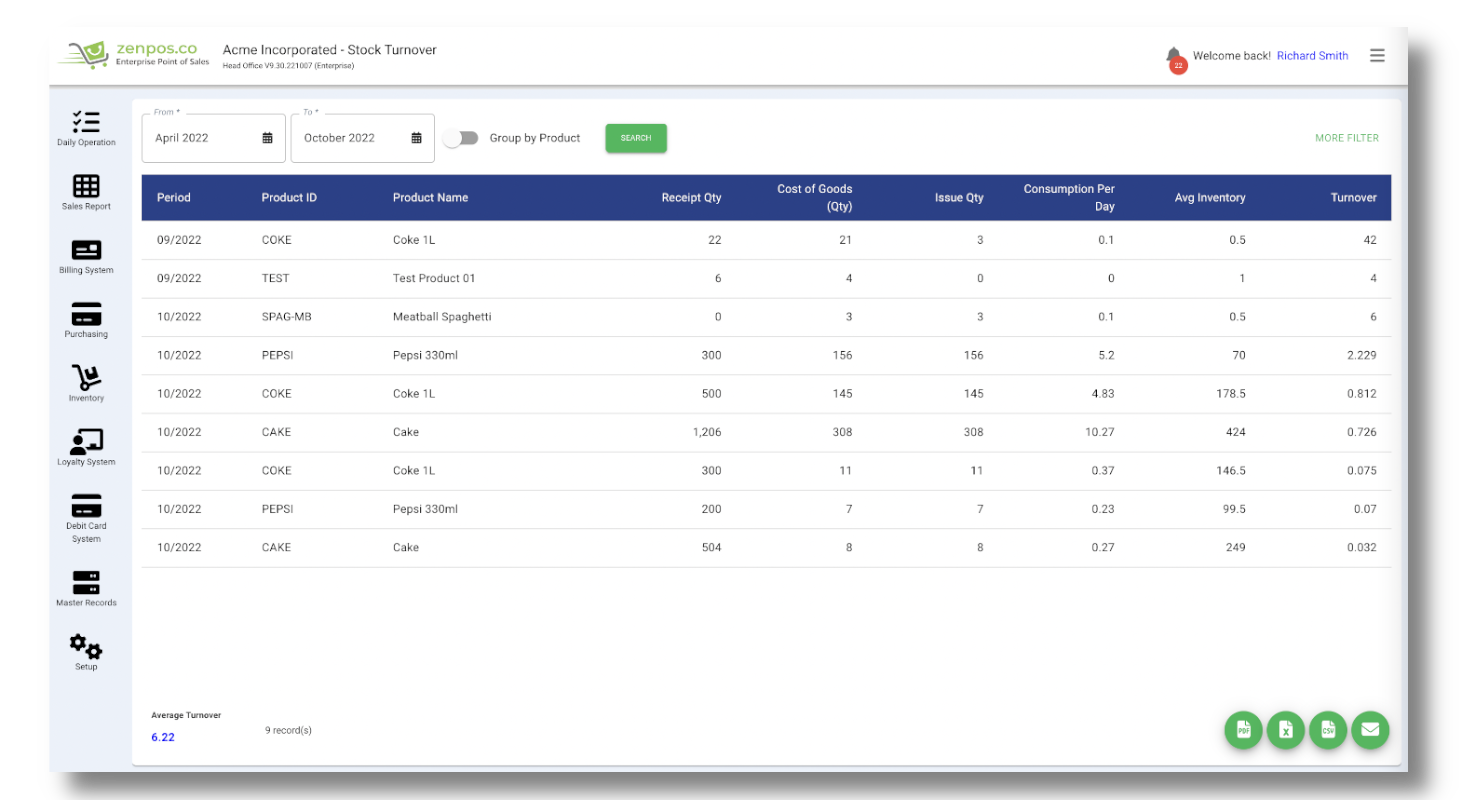

- Maintain the right amount of stock to reduce warehouse costs and free up cash while preventing stock-outs and overstocking.

- Minimize inventory shrinkage caused by errors or theft through proper accounting and paper trail.

- Track inventory expiry, non-moving inventory, and turnover rate.

- Perform stock count on each branch in offline mode and synchronize with the server after.

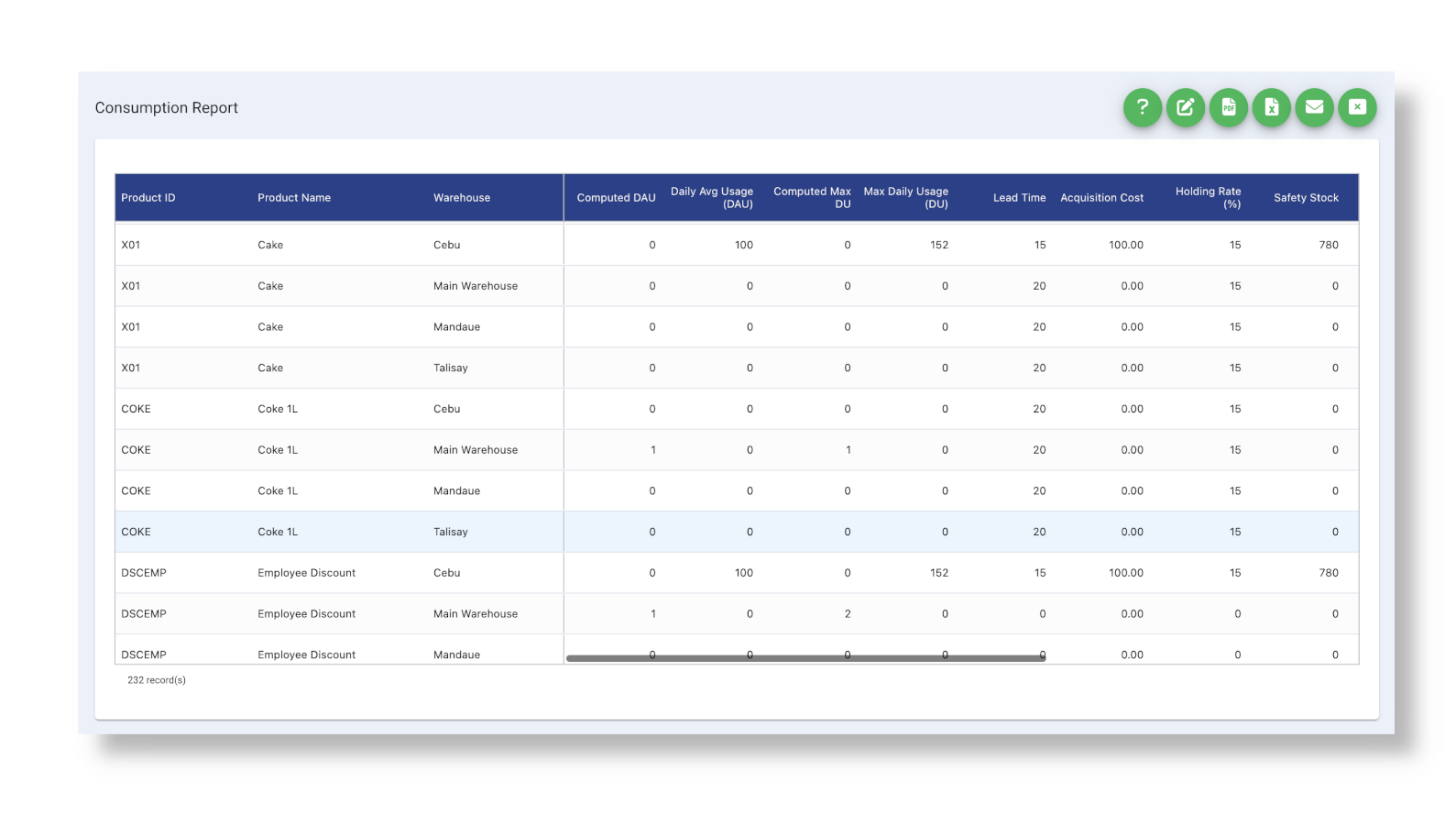

Forecast Demand

- Use the past sales performance to accurately compute for safety stocks, reorder points and reorder quantity. The system will then alert you when it hits these thresholds.

Features

- Create up to 30 inventory transaction types and customize each setting to minimize human errors.

- Track general inventory and serialized products.

- Define bill of material and automatically deduct the raw materials when assembled – useful for food and packed items.

- Transfer from one warehouse to another and wait until the target warehouse has actually received the items before updating the inventory.

- Define approval authorization for each inventory transaction before they can be posted to leave a paper trail.

- Access the inventory ledger and drill down to the source document.

- Allow POS to create inventory transactions in offline mode and automatically sync with the server.

- Track the device’s unique serial number or IMEI.